How we would construct the pipeline

Cadent is an experienced and trusted operator of gas pipelines.

We will make sure we bring our knowledge of constructing, operating and maintaining the existing gas network to this project.

The pipeline would be constructed predominantly using open trench (or ‘open cut’) techniques. Where open trenching is not possible or practicable, trenchless crossing techniques will be used. This will likely be to cross things like roads, railways and waterways.

Below we’ve provided an overview of open trenching and trenchless construction methods.

Open trenching

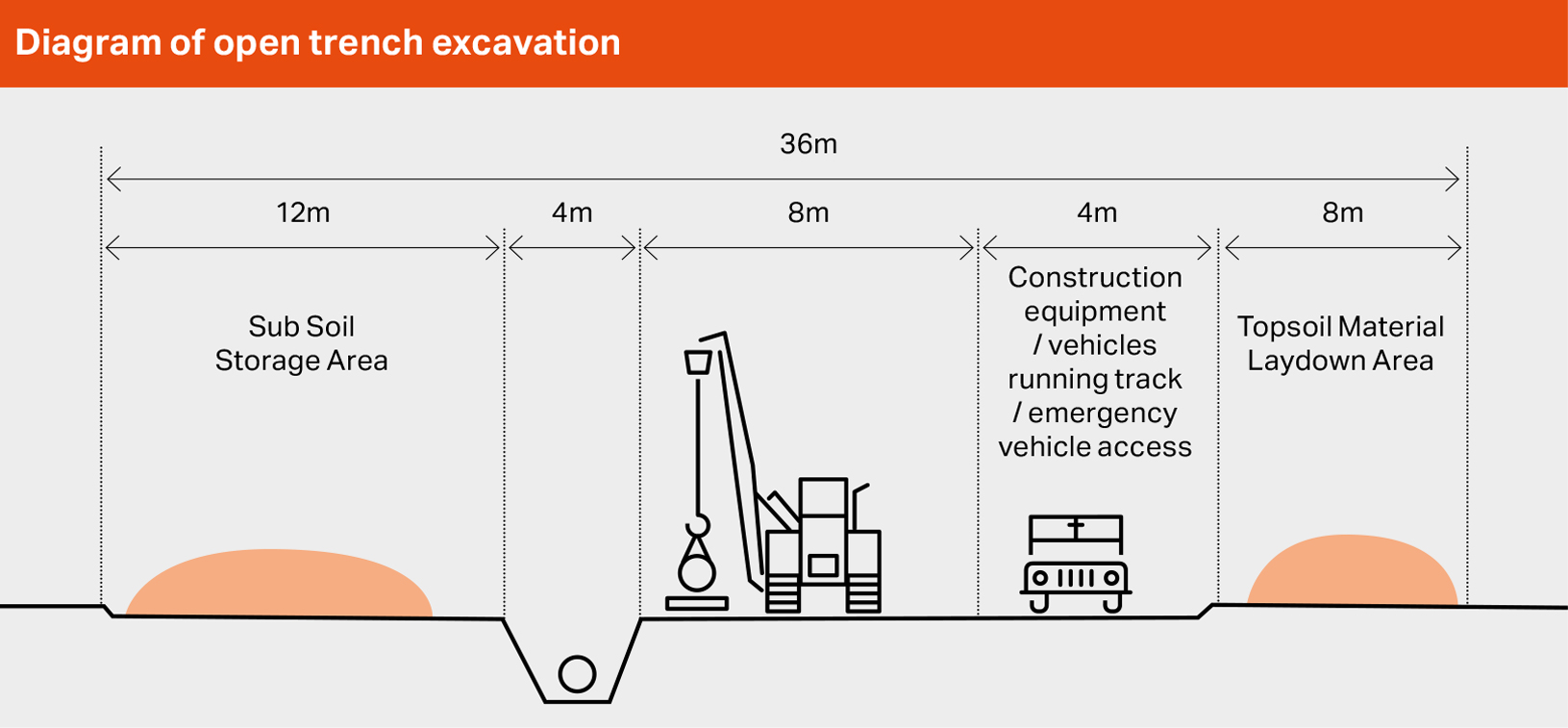

Typical working width - may vary depending on size of pipe or ground conditions. Click image to enlarge Pinch to zoom

Open trench (or ‘open cut’) excavation is the most common method for installing underground pipelines.

- Open trenching begins by marking out the total area within which construction work will take place.

- Topsoil is then carefully stripped and stored next to the pipeline route. Meanwhile, the pipeline is delivered in short lengths and placed on supports. These short lengths of pipeline are welded together into longer sections called ‘strings’.

- Testing is completed on each weld and a full inspection report produced before the welds are coated.

- The pipeline trench is then dug, with excavated material stored separately from the already stripped topsoil.

- The pipeline ‘strings’ are then lowered into the trench using special vehicles called ‘side booms’ (pictured) or excavators and welded to the pipeline that’s already been laid.

- The trench is backfilled using the previously excavated material and the topsoil is replaced.

- The pipeline is then hydrotested (filled with water) to prove the integrity of the fabricated structure and will pass rigorous checks prior to being commissioned.

Once the land above the pipeline has been fully reinstated it can be returned, as far as possible, to its previous use. We anticipate that open trenching will be the predominant technique we use to construct our underground pipeline.

Trenchless methods (for roads, rivers, other utilities and rail)

We’ll need to use trenchless methods at various points along the pipeline route, including to cross major roads, such as the M56, M62, M6 and watercourses like the River Weaver Navigation, Mersey River and Trent and Mersey Canal.

For more information about where we think we’ll need to use trenchless methods, visit the Knowledge Hub and view the Design Evolution Report.

In some cases, for engineering and environmental reasons, open trench methods are not viable so trenchless methods will be considered. Possible trenchless techniques that will be assessed as part of the design could include:

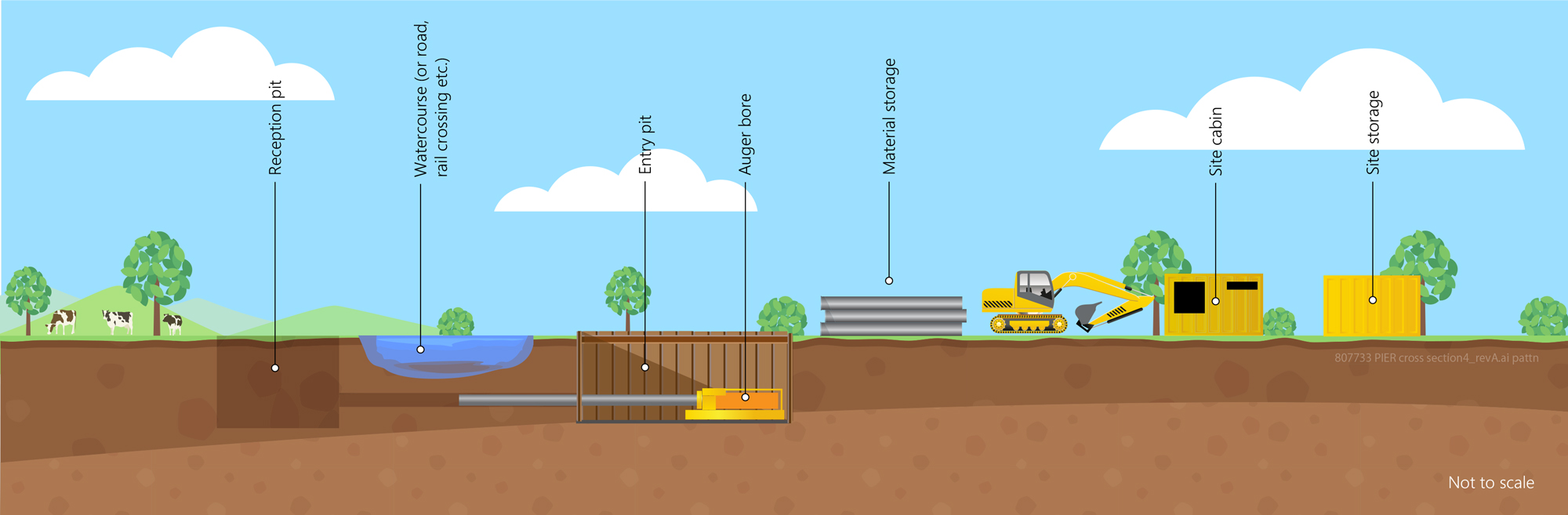

- Auger boring - Auger boring can either be ‘cased’ or ‘uncased’. For cased auger boring, steel or concrete pipe sections are pushed along the crossing section and material is removed by the auger drill inserted into the pipe. Following installation of the casing pipe, the hydrogen pipe is inserted with insulators to insulate and centralise the pipe in the casing. For uncased auger boring the hydrogen pipe is inserted directly into the ground with no casing.

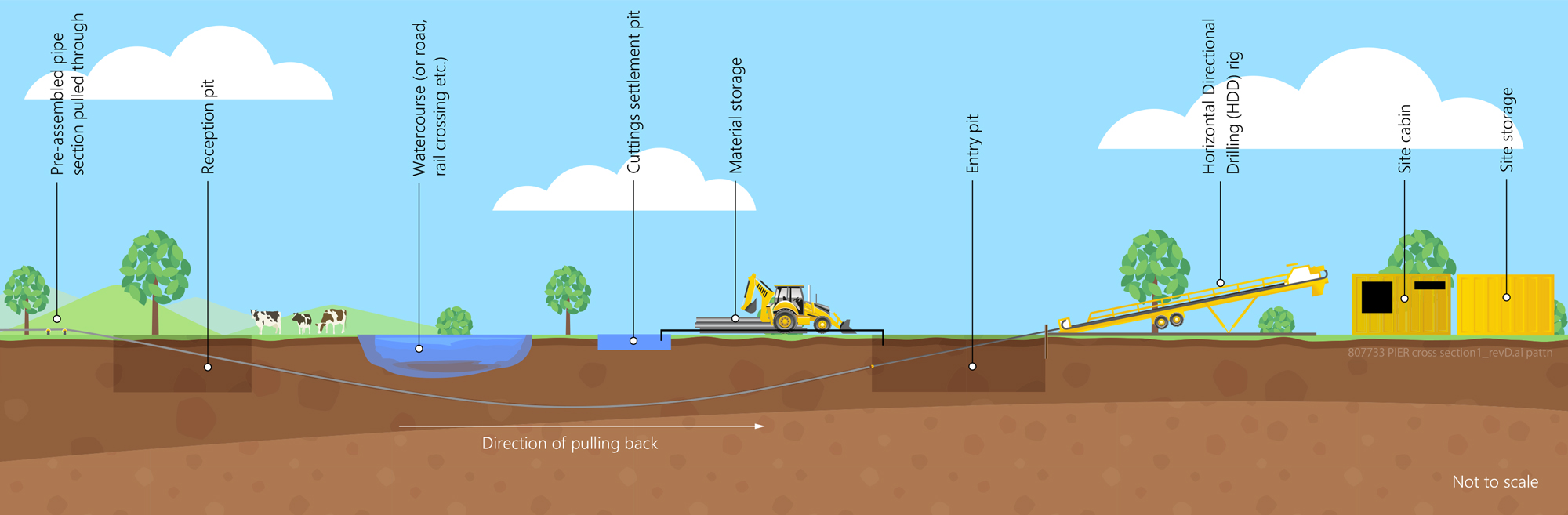

- Horizontal Directional Drilling (HDD) - HDD is typically used on longer trenchless crossings. It requires an entry and exit pit on either side of the crossing. A hole is then drilled beneath the crossing and the hydrogen pipe pulled back through the drilled tunnel.

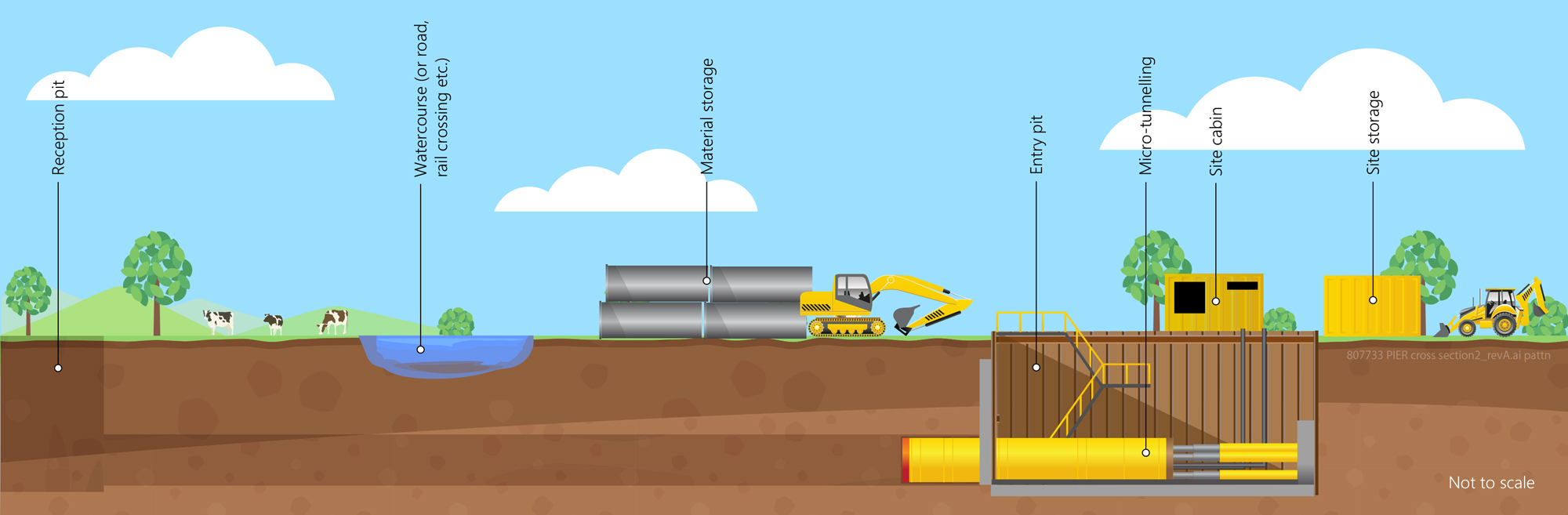

- Micro-tunnelling - Micro-tunnelling is especially useful for laying pipelines beneath large roads, railway lines, and other sensitive areas. A cutting tool / machine provides the mechanical excavation, which is generally controlled remotely above ground. Individual line pipes are then welded into a string pipe (a longer section of pipeline) and gradually pulled into the casing. Where space is limited, the pipe may be welded at the base of a shaft.

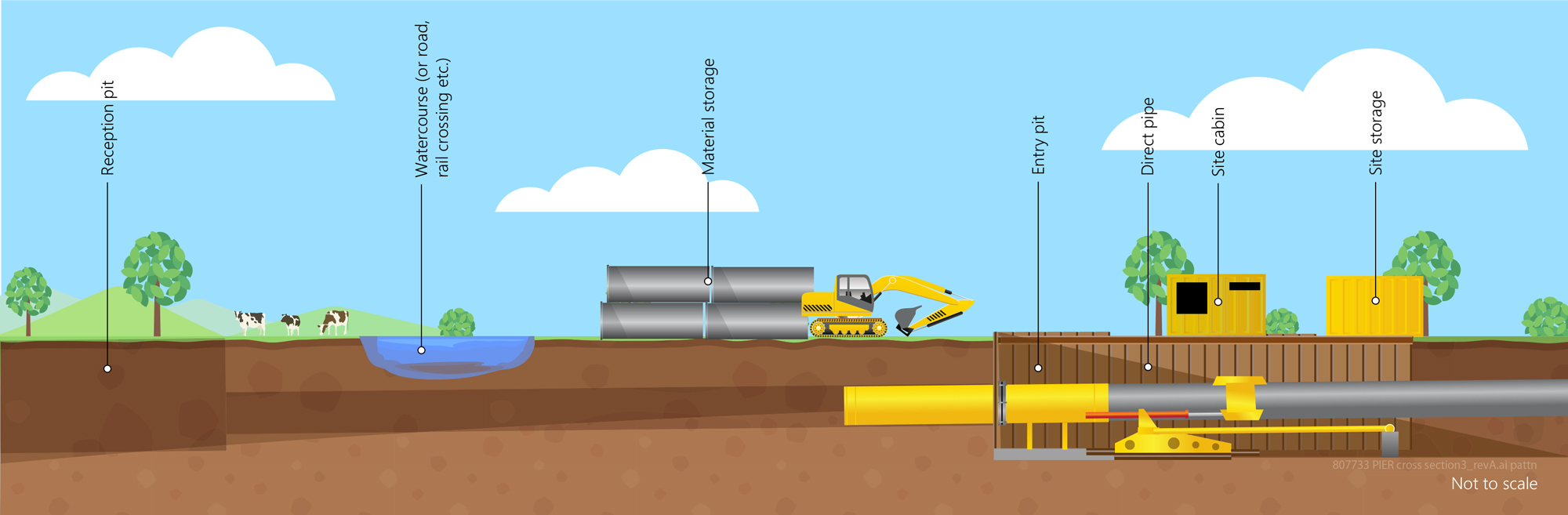

- Direct pipe - Direct pipe can be applied to short and longer trenchless crossings. This technique is similar in its method and set up as micro-tunnelling. However, the pipeline is installed directly into the ground behind the cutting machine, rather than being installed inside a completed tunnel.

Auger boring. Click image to enlarge Pinch to zoom

Horizontal Directional Drilling (HDD). Click image to enlarge Pinch to zoom

Micro-tunnelling. Click image to enlarge Pinch to zoom

Direct pipe. Click image to enlarge Pinch to zoom

Temporary construction areas

At certain points along the route we will need temporary construction areas. These will allow us access to build the pipeline and HAGIs, as well as to store construction materials. Once construction has finished, these areas will be returned to the land owner.

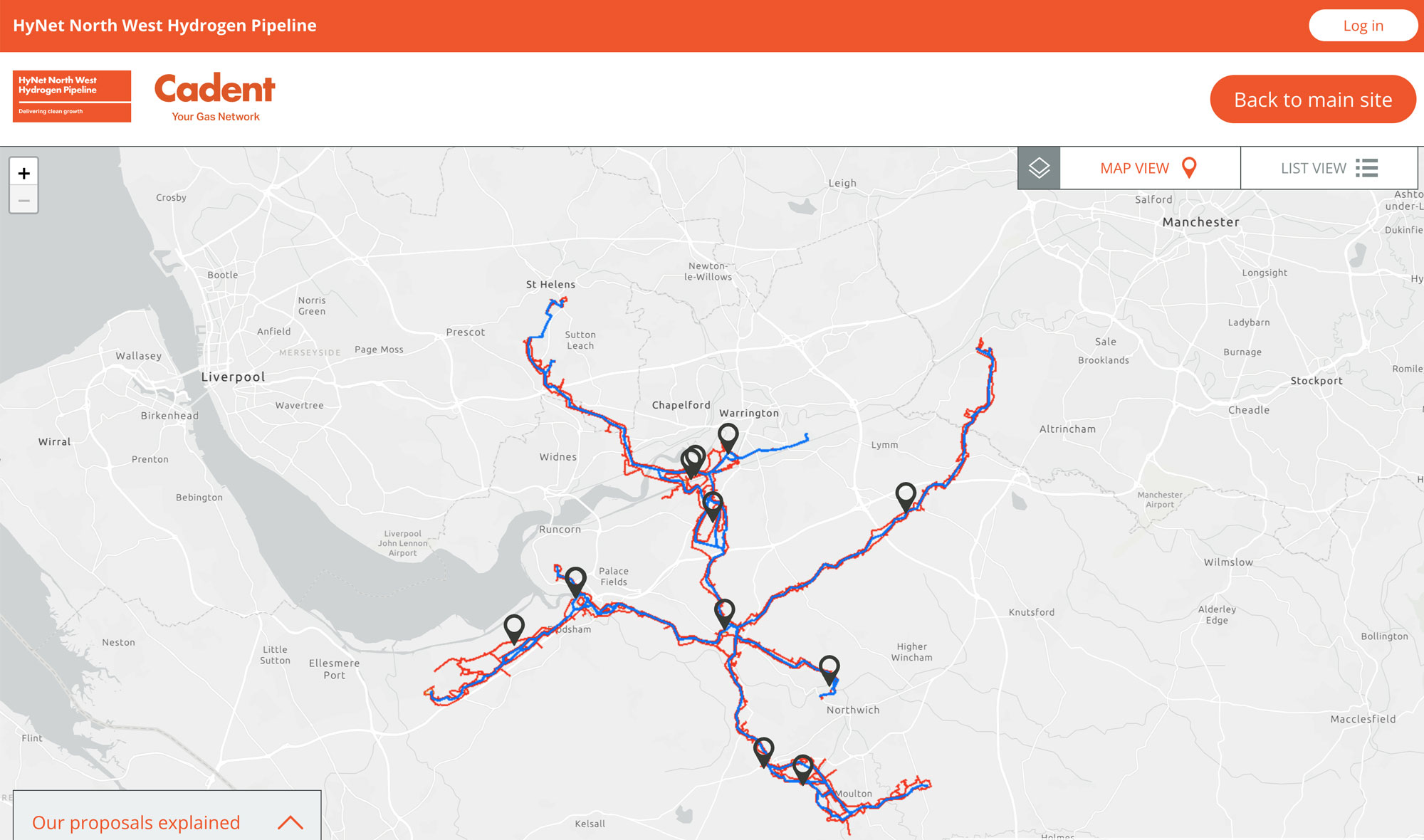

You can view the temporary construction areas in more detail via the interactive map or by contacting our project team for more information.

As part of our ongoing work, we’ll carry out further surveys of our construction areas and continue to liaise with local highway authorities to confirm they are suitable to use and support the safety of other road users. We will aim to carry out our construction as sensitively as possible and would welcome any feedback that can help us finalise our construction plans.

Temporary construction areas are likely to include:

- Temporary fencing – the requirements of which will be determined by security factors and what the land is being used for

- Temporary site signage and potentially other site safety requirements

- Temporary facilities for site personnel, there will be no lodging on any of our sites

- Temporary site drainage and possible watercourse crossings

- Temporary access to and from the site. Any access required will be agreed with the local highway authority. Any access tracks that are required will be determined by the conditions at particular construction areas.

Once we have finished using temporary construction areas we will, as far as possible, reinstate the land used to its previous use and return it to the land owner.

Interactive map (under review)

This map shows an overview of the proposals we presented at our second, statutory consultation – the area where our pipeline will be routed and temporary construction areas located, as well as potential Hydrogen Above Ground Installation (HAGI) and Block Valve Installation (BVI) locations.

See mapRegister for updates

Please register your contact details with us if you would like to be kept informed about our project.

Register here